Beneficiation Project

Innovative Wet Processing Solutions for Efficient Mining

At YG Group, we specialise in delivering high-grade iron ore concentrates through a state-of-the-art wet processing system. Our facility, designed for a 7.5 Mtpa throughput with the ability to expand to 10 Mtpa, utilises cutting-edge magnetic separation technology to produce 65-70% Fe concentrate. By leveraging existing infrastructure and employing a sustainable dry stack tailings strategy, we ensure efficiency and environmental responsibility. Our integrated export facilities allow for seamless storage and shipping, ensuring the reliable supply of premium ore to global markets.

Wet Processing Concept

- Nameplate 7.5 Mtpa feed throughput

- Designed for -14mm / >45% Fe

- 2-4 separate processing trains customised for ore type and producing 65-70% Fe conc.

- Utilise existing infrastructure to minimise capital requirements

- Option to expand to 10 Mtpa concentrate production

- Dry stack tailings and redevelopment strategy

Wet Processing Proposed Design

- Feed ore received at the existing rail tip pocket and transferred to existing Transfer Tower (TT01)

- Feed ore is transferred using existing stacker conveyor and stockpiled using new conveyor and radial stackers

- Feed ore is reclaimed using existing reclaim conveyor and transferred to 4 feed hoppers (6 hour capacity)

- Feed ore is transferred in three stage wet magnetic separation plant tailored to ore type, producing a 65-69% Fe concentrate

- Concentrate is stockpiled and reclaimed onto the main export conveyor and transferred into the storage sheds

- Tailings is dewatered and dry stacked onsite using conventional load and haul technics

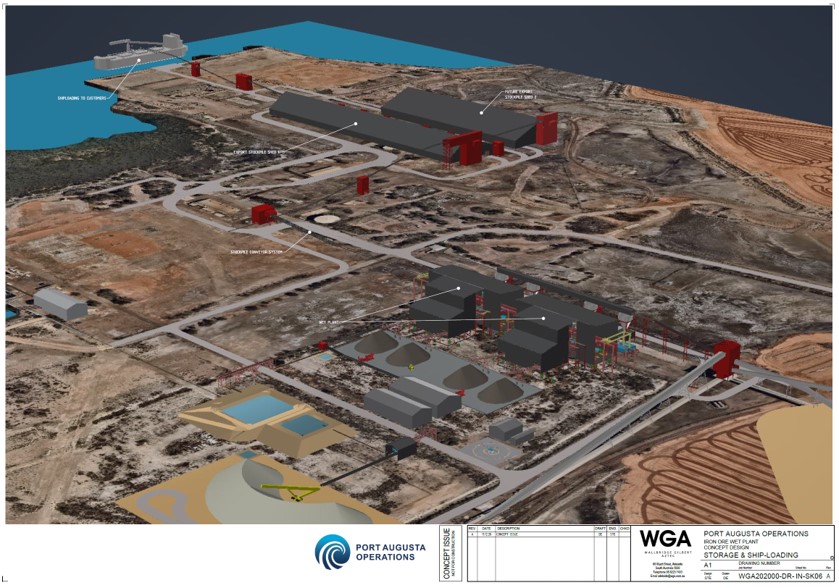

Wet Processing Integrated Export Facility

- Reclaimed magnetite concentrate is transferred onto the primary export conveyor

- Concentrate is transferred to a dedicated storage shed ready for export

- Concentrate can be stored and exported as stand alone product or blended during reclaim and export