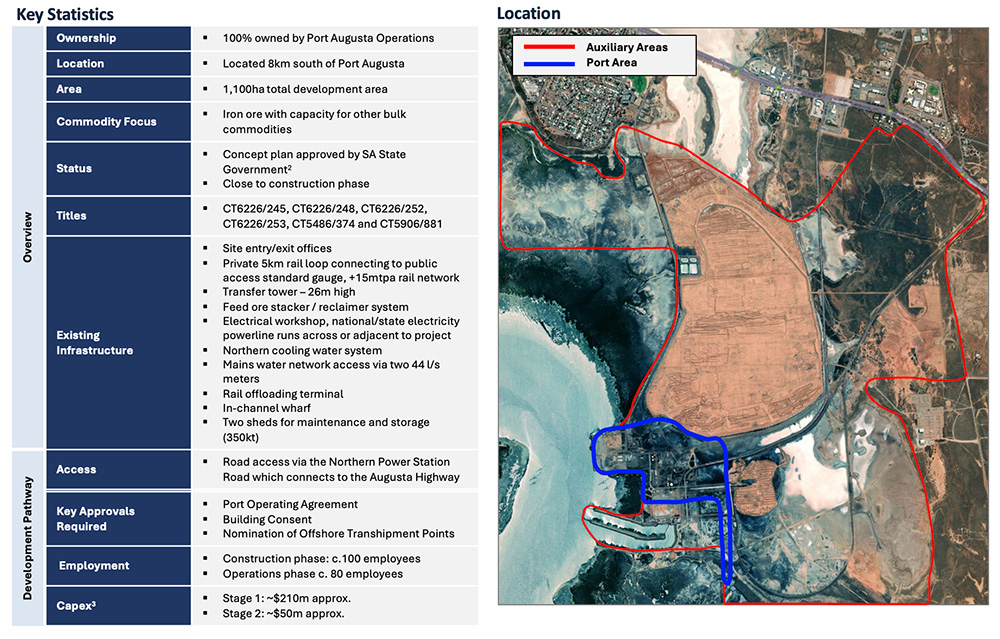

Export Facility

Project Overview

Port Playford Project is an innovative YG Group infrastructure development that is designed to meet the increased port facility demand as the vast iron ore potential of the areas north of Port Augusta are unlocked. With its low capital requirements and utilisation of existing infrastructure, Port Playford is poised to become a cornerstone of YG Group’s long-term growth and sustainability.

Port Playford’s design optimises the use of existing infrastructure to minimise capital expenditure while ensuring efficient operations. The port features a 5km single gauge rail balloon loop, a train load-out facility, and state-of-the-art stockpile and conveyor systems. The establishment of new product storage sheds and transfer equipment further enhances its operational efficiency, facilitating seamless trans-shipment operations.

Port Playford Snapshot

Port Playford is a highly strategic infrastructure asset sponsored by Department for Mining & Energy which provides for Crown development planning pathway¹

Source: Yonggang – South Australia Unlocking the Iron Ore Potential Presentation

1. Under the Planning, Development and Infrastructure Act 2016

2. Current variations are not expected to require reapplying

3. Additional Stage 2 mining related capex to be funded includes (1) pre-production capital (est. $10m) and an on-site, dry beneficiation plant at Buzzard (est. $35m); and (2) expansion of the existing mining fleet to support mining of new prospects (est. $30m)

Project Information

Brownfield Development Project

- 60ha Development site over 1100h freetitle lands owned by the Group

- Brownfield development with Special Employment zoning and EPA licence.

- Simple material handling design utilising existing infrastructure, including rail loop, train loadout, conveyor system and sea wall

- Existing customers – related iron ore producers and mine developers

- Development Approval received via ministerial sponsorship as major projects of the state.

Project Overview

- Up to 5mtpa export capacity (Stage 1), no dredging needed

- Iron ore focus, with optionality for other commodities

- Utilise existing infrastructure to minimise capital requirements

- Expand and optimise using a staged approach (existing infrastructures can support expansion up to 20mtpa)

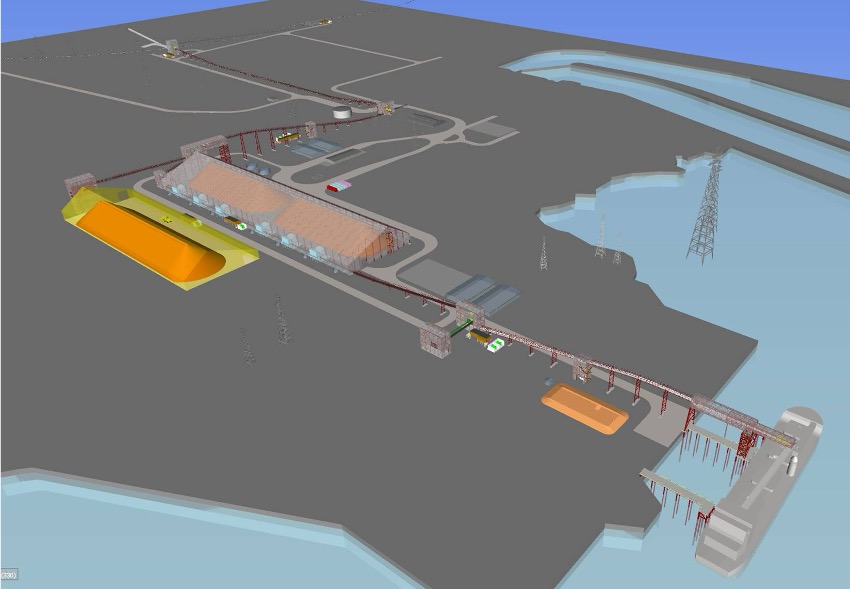

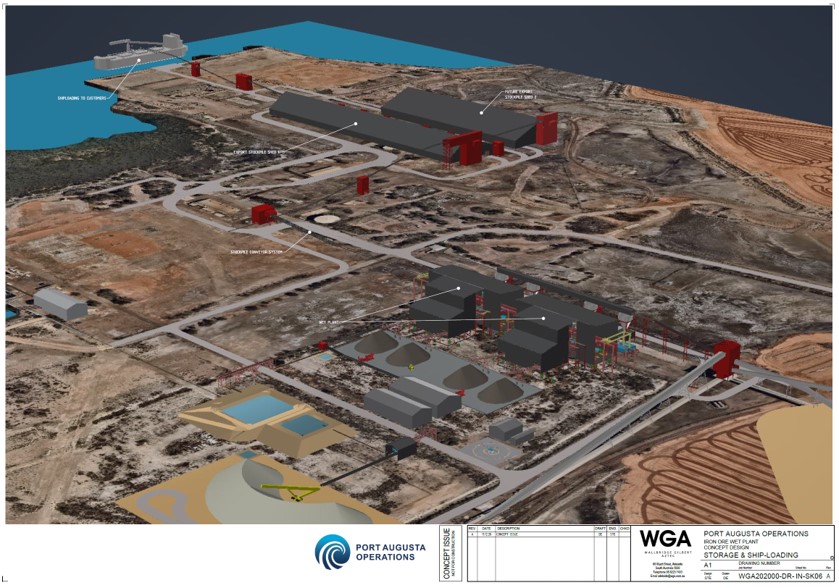

Proposed Design

- 80% heavy lifting building work has been completed;

- New stockpile conveyor system; associated with transferring material from freight carriages to the Storage Sheds;

- New product storage sheds (for up to 740kT) located adjacent to the wharf area;

- New transfer equipment for transfer of materials from the Wharf storage shed to the Barge loader;

- Strengthening of the in-channel wharf wall, new mooring dolphins, gangway and gantries for the transhipment barge to moor and berth against during loading.

DCIM100MEDIADJI_0164.JPG

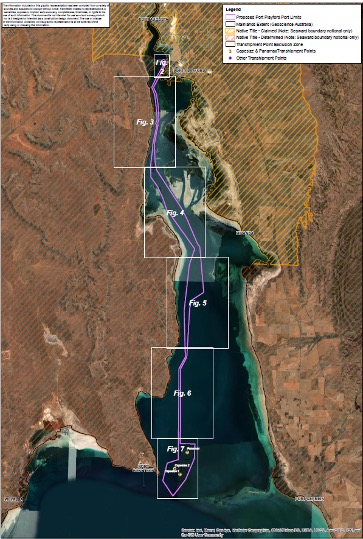

Transhipment Options

- Utilising a new self propelled, self loading and unloading transhipment vessel (16 500 t).

- Dredging not required – tidal cycles will not restrict vessel movements.

- Only second port capable of loading Cape size vessels

- Utilising new offshore transhipment points 28 Nautical miles from Port Playford.

- Negotiating Port Operating Agreement with the State Government

Regional Market / Users for Port Playford

- Identified key assets to support a +5.0Mtpa export facility and mineral processing business at Port Playford

Operational Excellence

Port Playford has been carefully designed to ensure the new load out facility, storage sheds and conveyor systems are seamlessly and efficiently connected to the existing rail and sea interface infrastructure.

Strategic Importance

Port Playford is strategically situated to serve key mineral provinces such as Braemar, Gawler Craton, and Curnamona. Its proximity to critical infrastructure, including rail and road networks, underscores its logistical advantages. This strategic location enables the port to efficiently handle commodity receivals from various directions, ensuring a robust supply chain from mine to market.

Trans-Shipment Viability

Port Playford’s utilisation of self-propelled, self-loading and unloading trans-shipment vessels allows for the efficient transfer of materials to ocean-going vessels. This eliminates the need for dredging and ensures flexible, cost-effective operations, capable of handling up to 5 million tonnes of iron ore annually in the initial stage, with potential expansion to 20 million tonnes per annum.

Sustainable Practices

YG Group is committed to sustainable development practices at Port Playford. The port’s design prioritises environmental conservation, leveraging existing infrastructure to reduce the ecological footprint. The strategic reprocessing of low-grade stockpiles into high-grade ore exemplifies YG Group’s dedication to environmental stewardship, turning potential waste into valuable resources.

Economic and Community Impact

The development of Port Playford is already delivering significant economic and environmental benefits, now housing a Green Cement production facility that has already led to significant job creation and local economic benefit. YG Group proactively engages with local communities striving to improving the social and economic wellbeing of the region.

Future Prospects

The port’s scalable design and strategic location ensure its long-term viability, positioning it as a critical asset in YG Group’s portfolio.